The biggest expectation of Electric Vehicle (EV) owners is undoubtedly to be able to "fill the tank" as quickly as a gasoline vehicle. Although ultra-fast DC charging stations such as 350kW exist today, these promised speeds are generally not maintained. The reason is simple: "Thermal Throttling." When batteries are charged at high power, they overheat, and the Battery Management System (BMS) is forced to slow down the charging speed to protect the cells.

This is precisely where the revolutionary thermal management system named Dectravalve, developed by the UK-based company Hydrohertz, comes into play.

The Source of the Problem: Traditional Cooling and "Hotspots"

The vast majority of existing EV battery cooling systems adopt a "monolithic" approach. That is, they attempt to cool the entire battery pack as a single large unit.

Details of Thermal Throttling

This approach causes the cells at the center of the pack to heat up much more than those on the edges. When these "hotspots" reach critical levels like 50°C to 56°C the BMS slows down charging. Independent tests show that the in-pack temperature difference in conventional systems can reach up to 12°C.

Dectravalve: Smart and Multi-Zone Thermal Management

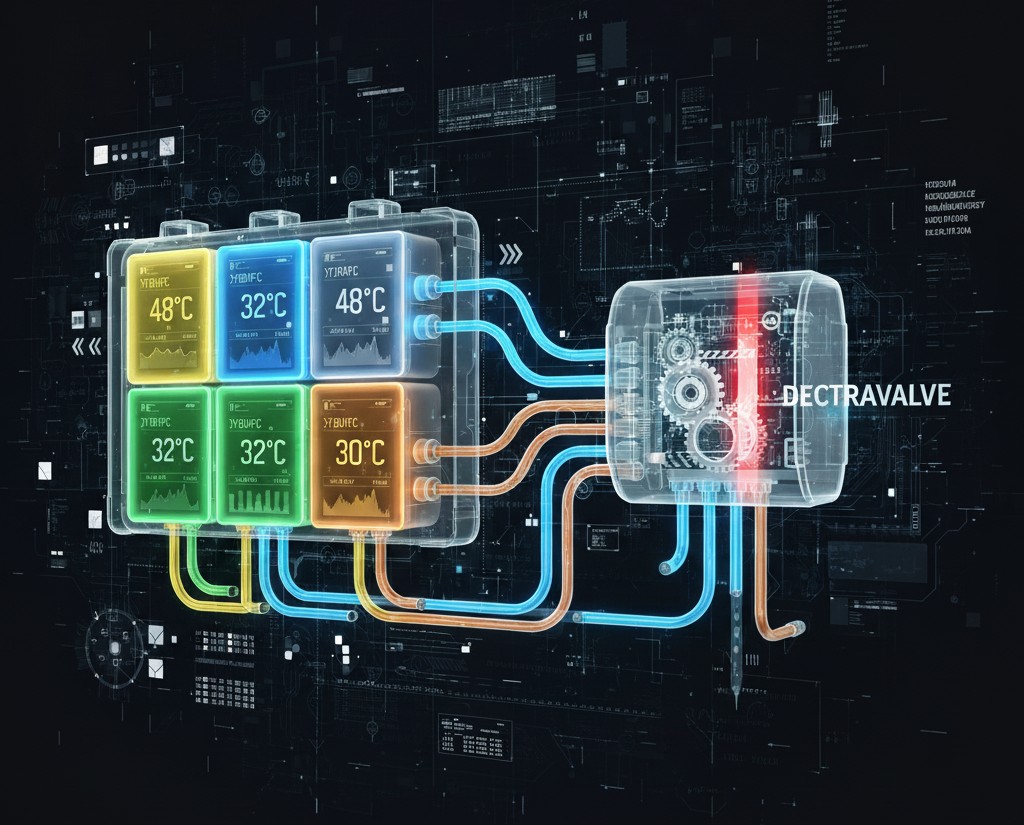

Dectravalve solves this problem by dividing the battery pack into four or more independent thermal zones. This system, which came to the fore with independent test results conducted by the Warwick Manufacturing Group (WMG) in 2024, uses digitally controlled smart valves.

How Does Dectravalve Work?

The system monitors the temperature of each zone separately. It directs the cooling (or heating) fluid only to the cell group that needs it, exactly as much as necessary. Most importantly, it physically prevents the heated fluid in one zone from "cross-flowing" into other, cooler zones.

The Revolution in Numbers: WMG Test Results

WMG's tests on a 100kWh LFP battery clearly revealed Dectravalve's potential:

- Temperature Ceiling: The hottest cell was kept below 44.5°C.

- Homogeneity: The temperature difference across the battery pack was reduced from 12°C to just 2.6°C.

Gains Beyond Fast Charging

This precise temperature control unlocks the "fast charging" capability. Since the battery remains homogeneous and safe, the BMS does not throttle the charging speed. This makes it possible to reduce a typical 10°C-80°C charge time of 30 minutes by up to 68°C, dropping it to approximately 10 minutes.

Longer Battery Life and Safety

Excessive temperature is the number one enemy of lithium-ion batteries and leads to cell degradation. By keeping the battery in its ideal temperature range, Dectravalve both extends its lifespan and reduces the risk of thermal runaway.

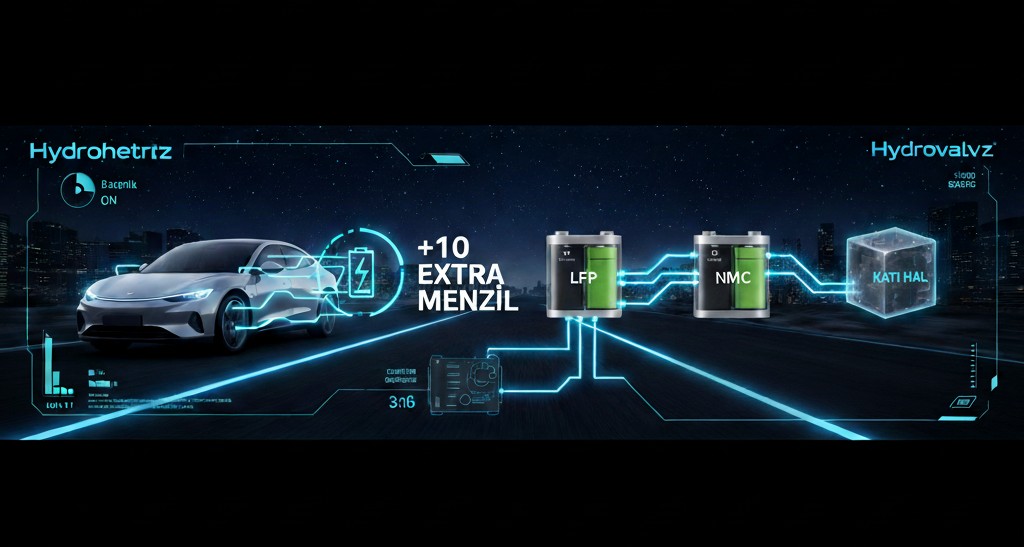

Increased Range and Technology Compatibility

The system optimizes battery efficiency not only during charging but also during driving. This can translate to up to 10°C extra real-world range. Furthermore, Dectravalve is chemistry-agnostic; meaning it can work with current LFP, NMC, and even future solid-state batteries.

A New Standard in the EV Market?

Hydrohertz Dectravalve has the potential to eliminate one of the biggest obstacles to EV adoption, namely the charging wait time. This technology opens the door to a future where electric vehicles can truly compete with their gasoline counterparts by solving the "thermal clamp" that limits the battery's potential, rather than the battery itself.